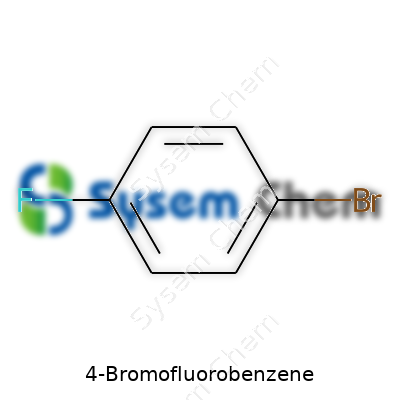

4-Bromofluorobenzene: Beyond the Basics

Historical Development

Back in the early 1900s, aromatic halogenated compounds started to grab the attention of chemists looking for new building blocks. Among these, 4-Bromofluorobenzene turned into a workhorse because of its strong structure and reactivity. Researchers in the 1960s, hunting for more effective synthetic routes to make pharmaceuticals, dyes, and agrochemicals, found that swapping out hydrogens on a benzene ring for bromine and fluorine opened up doors. Laboratories around the world gradually optimized methods for selective halogenation, setting up a foundation for the widespread use of compounds like 4-Bromofluorobenzene in both academic and industrial chemistry.

Product Overview

4-Bromofluorobenzene shows up as a clear, colorless to pale yellow liquid, and packs a punch due to its one-two combo of bromine and fluorine atoms on a benzene base. CAS number 460-00-4 usually identifies it in catalogs. Its formula, C6H4BrF, makes it a favorite for chemical transformations. Reliability in purity and consistency often leads chemists to reach for this particular molecule over the alternatives, especially for cross-coupling reactions. Through years of trade, producers have driven quality control tighter, and today you won’t find it full of unwanted byproducts if you stick with reputable suppliers.

Physical & Chemical Properties

The molecule weighs in at 175.0 g/mol and boils at around 151-153°C, based on pressure. Its density hovers near 1.6 g/cm³. 4-Bromofluorobenzene only dissolves a little in water, but it blends right into common organic solvents like ether, acetone, and chloroform. Its structure makes it stable under most lab conditions, but break the rules—strong light, heat, or an open flame—and it can decompose, sending off hazardous fumes. Its volatility and moderate vapor pressure push for some ventilation during use, especially in larger scale work where small changes in temperature spill over faster.

Technical Specifications & Labeling

Every bottle worth trusting carries high standards—purity above 98 percent, low levels of moisture, and tight control over byproducts like dibromo- or difluorobenzenes. In labeling, expect hazard pictograms, risk statements about skin and respiratory irritation, and guidance on safe disposal. Modern suppliers stick to the Globally Harmonized System (GHS) for safety, with batch-specific data for traceability. Details like UN number (UN 1993, if packaged in large enough amounts for transport), and its proper shipping name—“Flammable liquid, n.o.s.”—remove ambiguity for anyone handling or transporting the compound.

Preparation Method

Most synthetic labs produce 4-Bromofluorobenzene by starting with fluorobenzene. The standard method involves electrophilic aromatic substitution, using molecular bromine and an iron catalyst to push the reaction toward the para position. Post-reaction workup with aqueous sodium bisulfite and a quick extraction with diethyl ether brings the product out. Industrial-scale methods aim to suppress the formation of isomers—nobody wants ortho-bromofluorobenzene sneaking into a reaction pathway, so precision in temperature and stoichiometry matter. Green chemistry practices, such as solvent recycling and catalysis optimization, have trimmed the environmental impact over recent decades.

Chemical Reactions & Modifications

This compound reacts readily under metal-catalyzed couplings, like the Suzuki-Miyaura and Buchwald-Hartwig aminations. The bromine atom opens up the benzene ring to a new group, while the fluorine sticks around, giving a push-pull electronic effect. Chemists exploit these features in medicinal chemistry, tweaking the molecule to build structures they think might block disease at the molecular level. Other transformations, such as lithium-halogen exchange, produce useful intermediates for specialty chemicals and materials science. Over the past two decades, 4-bromofluorobenzene has featured in hundreds of patent filings for next-wave OLEDs, anti-viral drugs, and high-performance polymers.

Synonyms & Product Names

Across catalogs and research papers, you’ll find 4-Bromofluorobenzene hiding under several aliases: para-Bromofluorobenzene, 1-Bromo-4-fluorobenzene, and 4-fluoro-1-bromobenzene. Chemical databases sometimes flatten it into a molecular identifier, like PubChem CID 8807, but for frontline researchers it’s the structure and supply source that sticks. Different suppliers may tack on their own trade names or packaging codes, but the chemical backbone stays the same, offering easy reference for procurement or regulatory checks.

Safety & Operational Standards

Working with halogenated benzenes demands solid habits. Direct contact with skin brings irritation, and accidental inhalation of vapors can bother mucus membranes. Proper fume hood work and gloves ranked among the first lessons I learned in a teaching lab. Waste from workups needs careful containerization, given its persistence. Emergency plans for spills involve activated charcoal and fire suppression with foam. More recent industry guidelines highlight the need for routine air monitoring and personal protective equipment (PPE) tailored for organic solvents and reactive intermediates. Safety Data Sheets (SDS) provide the framework, but real safety comes down to methodical teamwork and strict attention during every stage, from opening the bottle on the bench to final waste disposal.

Application Area

You’ll spot 4-Bromofluorobenzene most often in research on new drugs and advanced polymers. Medicinal chemistry relies on its clean reactivity to build candidate molecules where both the electronic and spatial properties can be tightly controlled. Agrochemical labs use it to tweak pesticide scaffolds or probe new biological targets. Material science engineers reach for it while designing new coatings whose surface interactions matter even at the nanoscale. Not every compound survives the jump from lab curiosity to industrial staple, but this one keeps showing up because the bromine and fluorine pattern consistently delivers unique physical and chemical traits that other halogenations miss.

Research & Development

Academic labs and industrial R&D engines treat 4-Bromofluorobenzene as a trusted synthetic pivot. Researchers continually look for better, cleaner, and faster reaction routes using milder conditions, often publishing new catalyst systems that shave off time and cost. Pushes for greener chemistry drive innovation around solvent use, minimizing waste with recyclable media, and anaerobic methods that prevent off-gassing of dangerous byproducts. Many cross-disciplinary teams involve computational chemistry, predicting how further substitution on the benzene ring could alter biological potency with programs that barely existed a decade ago. Tighter collaboration with suppliers means batches get vetted right from production—characterization tools like NMR, GC-MS, and HPLC serving as the common language between synthesis and application groups.

Toxicity Research

Questions about health effects spurred studies analyzing how the compound travels and breaks down in biological systems. Inhalation brings mild to moderate respiratory irritation in lab animals. Skin contact, if left unchecked, leaves redness or sensitization. Chronic bioaccumulation doesn't appear as strong as with polychlorinated biphenyls (PCBs), but the risk prompts waste management strategies that capture and treat spent solvents. Work on environmental breakdown has mapped out degradation by UV-catalyzed processes and microbial breakdown. Occupational exposure limits aren’t widespread due to its specialty niche, but organizations still call for prudent minimization of direct exposure during all handling steps.

Future Prospects

Looking ahead, 4-Bromofluorobenzene looks set to play a bigger role in personalized medicine, where designer drugs rely on increasingly fine-tuned aromatic scaffolds. Growth of the electronics sector, especially for thin-film transistors and OLEDs, rides on continued innovations in organic molecules like this. As public pressure and policy turn toward sustainability, demand grows for synthetic routes that minimize waste, use safer reagents, and align with circular economy principles. Automated reaction development, powered by AI, now helps optimize reactions in silico, reducing both time and resource consumption. Ongoing advances in catalysis, especially with earth-abundant metals, may soon reshape how this compound gets made and where it ends up. Through flexible application and continuous improvement, the simple molecule that started as a bench curiosity has become an anchor in modern synthesis and a touchstone for what’s possible with thoughtful chemical design.

Breaking Down the Compound

Everybody uses chemicals in some way, even if a person never sets foot in a lab. Plenty of cleaning solutions, medicines, and materials we rely on each day start off as compounds built on rings of carbon. Among those, aromatic compounds play a big part. 4-Bromofluorobenzene stands out as one of the simpler, yet essential aromatic systems, especially for chemists working in organic synthesis or pharmaceuticals.

What’s Actually in 4-Bromofluorobenzene?

The backbone of this compound looks a lot like benzene, the classic six-carbon ring popular since the earliest days of chemistry classes. Instead of six hydrogens stuck to the ring, two of them get replaced. One gets a bromine atom, the other, a fluorine atom. To someone new to chemistry, that might not sound like much, but swapping out even a single atom can flip the story and turn a boring solvent into a key building block for medicines or advanced materials.

The name gives away the secret: “bromo” for bromine, “fluoro” for fluorine, and “benzene” for that familiar carbon ring. The “4” tells us the fluorine and bromine sit opposite one another, each sticking out from the ring like distant neighbors talking over a fence.

The Formula: C6H4BrF

Chemists love formulas because they sum up a lot of information at a glance. 4-Bromofluorobenzene uses a formula that looks like this: C6H4BrF. That means six carbons, four hydrogens, one bromine, and one fluorine. The math tracks with how folks build this molecule in the lab or look it up in a chemical database. Each element carries its own weight, both in the literal sense and also in terms of reactivity and safety.

Why Knowing the Formula Matters

Having the formula in hand lets chemists predict how 4-bromofluorobenzene will behave. For example, adding a bromine atom and a fluorine atom changes boiling points, reactivity, and even the safety profile. In practice, that means extra care goes into storage and handling. At my old university lab, no one touched brominated chemicals without gloves, goggles, and a strong fume hood running full blast. The fluorine makes it even trickier, since it brings both reactivity and the potential for nasty health effects if mishandled. Safety data sheets help, but knowing what’s in the compound always provides the first clue on what to expect.

In research, the formula guides everything, right down to disposal. Halogenated aromatics don’t go down the drain. Instead, chemical waste containers fill up, labeled by formula and date, and trained staff handle pickup. Mistakes cost time and risk lab safety. The simple act of knowing that C6H4BrF isn’t just a number — it’s a signal to keep a sharp eye on all handling procedures.

Solutions for a Safer Lab and Better Outcomes

Quality training remains the root solution for any chemical-related work. Making sure people learn the formula, structure, and risks of something like 4-bromofluorobenzene goes beyond rote memorization. It’s about understanding how small chemical tweaks can change everything. Every chemist, technician, and student benefits from lessons backed up by real-life examples and regular safety drills. And as labs shift toward greener practices, knowing which atoms create hazards or influence persistence in the environment leads to smarter substitute choices down the road.

Chemistry never stays static. More companies feel pressure to phase out substances that resist breakdown or create health issues. Laying a foundation of solid chemical knowledge, including the meaning behind every formula, helps solve bigger challenges down the line, from cleaner water to safer pharmaceuticals.

Why 4-Bromofluorobenzene Matters in Chemistry

4-Bromofluorobenzene sits among those chemicals that show up in the practical side of organic synthesis. This compound, a benzene ring with bromine and fluorine holding spots on it, isn’t something you find in household cabinets, but it plays a huge role in labs and manufacturing. When I’ve worked on research teams, we often saw 4-bromofluorobenzene pop up in lists for building more complicated molecules. Once you see how useful it is as a building block, it's hard to overlook the impact it has on pharmaceuticals, agrochemicals, and new material projects.

Sparking Pharmaceuticals and Agrochemicals

Pharmaceutical research often pushes to create molecules with fine-tuned effects in the body. Here is a case where the small tweaks make all the difference. 4-Bromofluorobenzene helps chemists insert both bromine and fluorine atoms into drug candidates at once, without jumping through unnecessary hoops. The bromine makes it easy to swap in new pieces by coupling reactions, a trick prized by medicinal chemists who hunt for better cancer drugs or treatments for chronic conditions. Studies have shown that drugs built off fluorinated aromatic rings can resist breakdown in the body longer and show better absorption.The benefits spill over into farming too. Modern pesticides and herbicides often claim some edge through tricky organic chemistry. Here, fluorine handles pests or weeds more effectively without getting washed away in the rain or sunlight. By using 4-bromofluorobenzene early in the process, scientists streamline the road to new crop protection tools.

Fueling New Materials and Electronics

Electronics manufacturers constantly search for special chemicals that can do more than sit on a shelf. Fluorinated aromatic rings, like those found in 4-bromofluorobenzene, influence how materials behave when layered inside circuit boards or display screens. During polymer design, chemists like to pick apart and rebuild these pieces so they can tune everything from heat resistance to flexibility. I remember projects focused on liquid crystals—without the right starting compounds, those displays end up cloudy or slow.For advanced materials, even a single fluorine or bromine atom can flip the switch on electrical properties. Companies making high-end insulation or specialty plastics rely on compounds like this to stay ahead of the curve.

Access for Academic and Commercial Labs

Cost and accessibility always control how fast discovery happens. 4-Bromofluorobenzene sits within reach for most research labs, since chemical suppliers stock it and keep it pure. That’s a break from some other reagents, where every order requires weeks of lead time or comes in tiny quantities.Practically, waste handling and safety always need attention. Researchers need gloves and eye protection, nothing fancy, but the safety data sheets push for well-ventilated spaces. Teams focused on green chemistry look at routes that cut out toxic byproducts during reactions.

More Smart Solutions in the Pipeline

Researchers keep working on better, cheaper ways of making 4-bromofluorobenzene. It comes down to finding routes that save energy, reduce hazardous waste, and make it greener from start to finish. I’ve seen plenty of students in university labs using it as a model to learn how new catalysts work, which brings fresh minds into the game.Looking at the big picture, the compound shows how even small molecular changes open up huge possibilities in science and technology.

Getting Real with Lab Chemicals

Working in a chemistry lab taught me pretty quickly that even clear liquids can pack a punch. Take 4-Bromofluorobenzene. It looks harmless—transparent, with a sharp, sweetish odor—but this stuff brings a set of risks that most folks outside of the lab don’t even consider.

Why Handling 4-Bromofluorobenzene Demands Respect

Just one whiff can irritate your nose and throat, and spilling it on bare hands causes immediate discomfort. Nitrile gloves aren’t a suggestion—they’re a necessity. Splash goggles kept me safe more than once. As a halogenated aromatic, it isn’t just flammable, it’s toxic. Without a fume hood, any amount of vapor will hang in the air, ready to irritate skin, eyes, and lungs. I’ve seen well-ventilated rooms make all the difference, especially when someone forgets a beaker out.

Personal Protective Equipment Takes Priority

People often underestimate protection. A real, tight lab coat blocks splashes. Closed-toed shoes beat sneakers, especially if something spills. My experience tells me to always double check my gloves for holes—and change them after any direct contact, no exceptions. Chemical goggles shouldn’t be swapped for regular safety glasses either. Standard glasses don’t seal around the face, and splashes never warn you before they hit.

Working Smart Means Labeling and Isolation

Labels must show full chemical names. Skipping thorough labeling wastes time and puts coworkers at risk. Storing 4-Bromofluorobenzene away from heat sources and oxidizers isn’t optional. Flammable cabinets, chemical-resistant trays, and tight-sealing containers are basic, non-negotiable storage steps. Never share tools between incompatible chemicals—this tip saved me after I saw a benchmate nearly cause a fume hood fire with careless pipetting.

Spills and First Aid: Act Fast, Not Fancy

Quick response matters. I once witnessed a small spill escalate because nobody owned up to it. Covering spills with absorbent, scooping with a plastic spatula, then bagging waste for hazardous disposal helps remove danger fast. Skin contact means a 15-minute wash—no shortcuts. Eyes need a direct trip to an eyewash station, even for “small” splashes. Don’t take chances hoping symptoms will fade, since halogenated aromatics love delayed effects.

Training, Documentation, and Communication

Every staff meeting, we reviewed incidents and near-misses. This habit forced us to confront mistakes and learn as a team. Material Safety Data Sheets are more than just paperwork—they spell out fire hazards, disposal rules, and what to do if things go south. I found real value in reviewing case studies of lab accidents, which gave us practical steps to prevent the same problems. Open conversations, not just rules, kept my lab running safely.

Balancing Ambition with Caution

Earning trust with hazardous chemicals means respecting the risks they pose. My time in the lab convinced me that complacency isn’t an option. Safety isn’t just about rules or equipment—it’s a mindset, built through teamwork, clear labels, sharp memory, and taking every “little” risk seriously.

Real Impact of Purity in Everyday Labs

Walking through a chemical lab, you start noticing how the tiniest impurities can turn a neat experiment on its head. With 4-Bromofluorobenzene, anyone hoping to work on pharmaceutical intermediates or advanced materials keeps a close eye on details. Purity isn’t a matter for the paperwork. It plays out in the reliability of each synthesis, the sharpness of a finished product, and even someone’s safety. Labs using this compound tend to buy material labeled “99%” or “99.5%” pure. Some call this “analytical grade” or “high purity,” but numbers say more than marketing: if you’re seeing 99% or higher, it fits advanced organic synthesis well.

Purity Specs Are More than a Number

Those who’ve tried to chase high yields in organic chemistry know small contaminants don’t just disappear—they sneak into reactions, build up side-products, and cause headaches during purification. Imagine working on a multi-step process with 4-Bromofluorobenzene. At 98%, you sometimes end up with strange byproducts. The last decimal point means cleaner end results and more predictable outcomes. Chemists value gas chromatography (GC) over just melting points or thin layer chromatography (TLC) for a good reason. GC gives a clear breakdown of even stubborn traces left behind at manufacturing or packaging facilities.

Trust in Raw Material, Trust in Results

4-Bromofluorobenzene’s quality connects straight to the trust we place in suppliers. Good sources lay out a certificate of analysis (CoA) for each batch. This isn’t just paperwork. It’s a real document that spells out purity, residual solvents, water content, and limits for heavy metals. For every new batch, we check the lot number matches what the database says and comb through the CoA line by line, especially if regulations for drug or electronics precursors play a role. Not all impurities cause the same trouble. Even a bit of moisture—often given as Karl Fischer water content—can set off unwanted side reactions. Nobody likes seeing their expensive catalysts destroyed by a lazy droplet.

Why Specs Vary Store to Store

Every supplier seems to advertise their own numbers. One brand points to 99.0%, another brags about 99.7%, and a third throws out “trace metals below 20 ppm.” Sometimes, packs meant for teaching labs offer only 97%. Low-cost bulk orders for demonstration or screening might drop a percentage off. Working in industrial synthesis, the threshold feels less negotiable. If the project calls for custom pharmaceuticals or optoelectronic materials, specs climb higher—sometimes with extra tests for halogen content or UV-Vis contaminants.

Getting the Best Out of What You Buy

In my own corner of chemistry, I’ve seen groups use a chunk of budget to upgrade from “practical grade” to “high purity,” just to save days of troubleshooting. Every department that spins up new molecules for biotech or electronics knows that starting pure keeps things on schedule. To stretch a budget, someone may filter or distill lower grade material themselves, but this chews up staff time. For a process with FDA oversight or patent protections, cutting corners isn’t worth the risk.

Working Toward Higher Standards

Information matters. Labs benefit when suppliers describe their analytical methods, identify major and minor impurities by GC-MS, and show batch-to-batch consistency. Comparing certificates, running an occasional internal check, and giving feedback to suppliers raise the bar over time. As more engineers and scientists share data, the market nudges toward transparency—and with that comes safer discoveries and better products downstream.

Understanding 4-Bromofluorobenzene

4-Bromofluorobenzene looks pretty straightforward at first glance—clear, colorless liquid in a small labeled bottle. Still, looks alone never tell the full story, especially when working with chemicals in the lab or industry. Many folks learn this the hard way, sometimes through trial and error, others by closely reading datasheets and handling protocols.

Where Things Can Go Wrong

Several years back, I watched a team store flammable solvents without much thought—top shelf, next to acids, right below bright windows. The results usually aren’t dramatic at first, but bad habits stack up, and safety takes the hit when nobody remembers who left the bottle out. It's never a small issue when dealing with substances like 4-Bromofluorobenzene. This chemical can ignite given the right conditions and reacts with strong oxidizers and bases. Those reactions rarely turn out well.

Why Proper Storage Conditions Make a Difference

Keeping 4-Bromofluorobenzene in check means minimizing exposure to heat, sunlight, sparks, and open flames. Over time even small rises in temperature can build up pressure inside containers, especially if they're not sealed tightly. There’s a clear reason most chemical suppliers recommend a cool, dry, well-ventilated place. Sunlight transforms clear liquid into a potentially risky one. Humidity or leaks in the cap can introduce contaminants, and those lead to dangerous reactions.

Trust in Personal Experience Backed by Science

I’ve kept plenty of sensitive chemicals over the years, and I remember coming in one Monday to find a faint smell in the storage room—a warning sign I now recognize instantly. One overlooked cap, more warmth than usual in the room, and the tension rises quickly. Science backs this up: volatile organics want a steady, cool environment. Ideally, temperatures stay under 25°C (77°F), away from sources of ignition. Fire cabinets rated for flammables give added protection, and chemical compatibility comes into play—never next to acids, bases, or oxidizers.

Supporting Facts and the E-E-A-T Approach

Lab safety studies highlight human error as a leading cause of chemical accidents. Simple steps bring down risk, yet many skip labels and inventory reviews—those matter just as much as fancy fume hoods. The Center for Chemical Process Safety notes that isolation, clear labeling, and ventilated storage space keep statistics low for accidents involving aromatic halides. That matches my experience: visibility, vigilance, and good housekeeping rules beat fancy gadgets every time.

Managing Risks Starts with Small Changes

Old habits die hard, but it’s possible to set up better routines. Double check seals and caps after every use. Install temperature monitors or low-cost sensors if the space isn’t already climate-controlled. Inventory checks keep containers in date and in shape. Staff training should cover not just what a chemical does, but exactly where it belongs at the end of the day, and what not to store nearby. In many cases, smart storage saves more trouble than expensive repairs after a spill or incident.

Toward Safer, Smarter Chemical Handling

Handling something like 4-Bromofluorobenzene isn’t about fear, but about respect for the risks. Attention to storage conditions cuts down on mishaps and keeps people safe. The lesson sticks—protect yourself, your space, and your colleagues, because a little extra care with every bottle adds up to a safer lab or workshop for everyone.