Phosphorus Tribromide: An In-Depth Overview

Historical Development

Chemists began studying phosphorus tribromide as early as the nineteenth century, a time when curiosity about new methods for transforming organic compounds shaped the path of industrial chemistry. Researchers like Pierre Eugène Marcellin Berthelot and his contemporaries found that reactions using phosphorus compounds produced new possibilities in synthesizing materials and intermediates. As the pharmaceutical industry climbed in complexity during the twentieth century, phosphorus tribromide stood out for its reliability in halogenation reactions, especially during wartime when raw material shortages forced chemists to innovate with whatever was available. By bridging access between phosphorus sources and potent brominating agents, this compound carved out a stable place in chemical manufacturing, a spot it holds to this day.

Product Overview

Phosphorus tribromide, known in laboratories by its shorthand PBr₃, plays an important role in both research and large-scale industry. This reagent is used day in and day out to replace hydroxyl groups in alcohols with bromine. The conversion stands out as a straightforward route to producing alkyl bromides. PBr₃ is a colorless to pale yellow liquid, producing dense fumes in moist air. Companies market it primarily to chemical plants and pharmaceutical companies, where it’s valued for both reliability and predictability. Supply chains focus on purity, since small impurities can spoil reactions downstream. Quality control teams carefully verify every drum, blending experience with tight standards to guarantee customers get exactly what the process demands. In short, PBr₃ remains a building block — most chemists meet it early in their careers, often with a touch of respect (or caution) in their voice.

Physical & Chemical Properties

Anyone who’s poured phosphorus tribromide notices its oily texture and pungent odor right away. At room temperature, the liquid weighs in with a density close to 2.85 g/cm³ and boils just over 175°C. One whiff of released fumes makes its reactivity obvious. Around water, PBr₃ hydrolyzes immediately and violently, releasing hydrogen bromide and leaving behind a mess of phosphorous acids. Solubility in most organic solvents is good, making it handy for those who need to keep it in solution. In terms of stability, storage containers need to be airtight, and the slightest bit of moisture ruins the batch. PBr₃ also reacts with alcohols, carboxylic acids, amines — making it a chemist’s tool for transformation, though never one to handle casually. Engineers care about melting and boiling points, reactivity toward common solvents, and shelf-life — these details drive storage choices and shipping rules more than pretty much anything else.

Technical Specifications & Labeling

Manufacturers supply phosphorus tribromide at industrial purity — usually at least 99%, judged by acid-base titration or gas chromatography. Labels highlight moisture content and trace impurities, such as phosphorus pentabromide or unreacted phosphorus, which can pop up from inconsistent batch conditions. Every drum or canister ships with a set of hazard warnings, emphasizing corrosiveness and reactivity with water, per international shipping requirements. Transport containers must meet UN specifications, with clear labeling to avoid accidents. Material safety data sheets follow local regulations but most agree on certain points: significant hazards, steps for first aid, and recommendations for personal protective equipment. Standards mean real safety for workers, end-users, and the environment around production sites.

Preparation Method

Production of phosphorus tribromide looks simple on paper but demands sharp control in the plant. Companies react elemental red phosphorus with liquid bromine under strictly anhydrous conditions. Usually, the plant adds phosphorus to a reactor, purges it with an inert gas like nitrogen, and then slowly adds bromine, keeping the temperature in check with external cooling. Technicians monitor the color change and gas evolution as the reaction proceeds, drawing samples to test for completeness. The product passes through vacuum distillation, scraping off any unreacted material or higher phosphorus bromides, before packaging in moisture-free containers. These steps sound routine, but every operator appreciates the risks: both components react explosively with water, and bromine’s toxicity creates major ventilation challenges. Quality counts on discipline, both in the control room and in the plant floor, to get right every time.

Chemical Reactions & Modifications

Phosphorus tribromide serves as the go-to reagent for transforming alcohols to alkyl bromides, a foundational step in making a wide range of drugs and specialty compounds. The reaction runs by a nucleophilic substitution, swapping the hydroxyl for a bromine atom and turning stable alcohols into highly reactive alkyl bromides. Carboxylic acids also react nicely with PBr₃ to give acyl bromides, which opens the door to even more chemistry. Some chemists use it for rearrangement reactions or to prepare organophosphorus intermediates, particularly when planning to build complex organic scaffolds. PBr₃ can also convert some amines and other heteroatom-containing molecules, challenging researchers to explore broader reactivity with custom-designed substrates. Many experimental modifications involve playing with solvents or controlling reaction temperature to tweak yield or selectivity, but the core chemistry has stood the test of time. Anyone tackling a new organic synthesis will find it hard to avoid this reagent for long.

Synonyms & Product Names

People refer to phosphorus tribromide by many names, proof of its long and broad history. Among chemists, PBr₃ serves as a quick abbreviation. Older texts use the phrase “tribromophosphane,” while trade catalogs sometimes list it as “bromophosphorus” or simply “phosphorus (III) bromide.” International shipping records and regulatory filings report it under CAS number 7789-60-8. In some circles, its reactivity toward water earned it the nickname “phosphorus bromide water splitter,” although this label never took hold outside of specialist discussions. No matter the name, the same clear liquid emerges from production facilities around the world, with buyers caring much less about terminology and much more about price, purity, and speed of delivery.

Safety & Operational Standards

Anyone who’s worked with PBr₃ never forgets the sting of its fumes or the way it reacts to the faintest humidity. Personal experience in labs and plants shows that gloves, chemical aprons, and face shields save skin and lungs from real harm. Emergency showers stand ready near bench tops, and strict rules forbid handling outside fume hoods. Every shipping container demands careful inspection for leaks, since exposure brings a real risk of severe skin burns, eye damage, and potentially fatal breathing difficulties. Containment protocols require airtight seals on storage tanks, constant monitoring for leaks, and automatic ventilation to move any stray gas outdoors. Spills call for specialized neutralizing chemicals, and plant operators keep solid soda ash and absorbent pads nearby just in case. Training updates every year as new incidents add to the industry’s collective caution — nobody considers these warnings optional or bureaucratic.

Application Area

Phosphorus tribromide rides the backbone of the pharmaceutical and chemical industries thanks to its role in assembling complex molecules. Many vital medications — especially those built on alkyl bromide intermediates — trace their origins back to this compound. Agrochemical manufacturing also depends on it for making pesticides and herbicides, often in the form of specialized bromine-containing chains that boost yield or improve pest resistance. Flame retardants, dye intermediates, and specialty plastics businesses each tap into supply contracts, counting on regular shipments to keep manufacturing lines humming. University chemistry departments and research organizations keep it as a standard reagent, training new generations of chemists in careful handling. Every application group approaches risk and reliability from a different angle, but all agree: PBr₃ earns its place through versatility and directness.

Research & Development

Much of the world’s work on phosphorus tribromide focuses on improving safety, efficiency, and downstream compatibility in finished products. Process chemists run studies on greener solvents and attempt to cut waste, especially the hydrolytic by-products often blamed for corroding plant equipment. Researchers test alternative preparation pathways using electrochemical or catalytic techniques, searching for routes that reduce hazardous input or offer more control over product quality. Another fertile ground involves designing new ligands or PBr₃-modified intermediates for catalysis, aiming to expand the role of phosphorus chemistry beyond traditional transformations. University labs run experiments on the fine details of reaction mechanisms, guided by advanced spectroscopic tools unavailable a few decades ago. These innovations don’t just show up in new patents; they shape day-to-day industrial operations, making processes safer and more sustainable.

Toxicity Research

Toxicologists pay serious attention to phosphorus tribromide. Decades of animal studies and workplace tracing prove the danger: even brief exposure to its fumes can scar lung tissue, trigger severe allergic reactions, or cause rapid chain reactions leading to systemic poisoning. Skin contact leaves chemical burns and deep scarring, with eye exposure carrying risks of permanent vision loss. Regulatory bodies enforce exposure limits and keep pushing for tighter controls as new studies show long-term effects. Researchers investigate not only acute toxicity but also the environmental fate of spills and releases, fearing persistent contamination of soil or water. Hospitals near chemical plants receive regular updates on best practices for treating exposure cases, and emergency response teams drill scenarios involving large-scale releases to minimize casualties. All this research matters, because the chemical’s value doesn’t erase the risks — it pushes for smarter, faster ways to keep workforces and neighborhoods safe.

Future Prospects

Innovation keeps changing the role of phosphorus tribromide. Industry leaders look for greener methods to make the compound, including recycled phosphorus recovery and non-toxic brominating partners, both to cut production risks and secure raw materials as regulations tighten. Academic scientists mix machine learning with chemistry, aiming to predict new reaction pathways and make PBr₃-based routes safer and less wasteful. Sustainable chemistry groups design microreactor technologies able to limit worker exposure and shrink plant footprints, lowering both costs and hazards. Other researchers work with regulatory bodies and advocacy groups to set realistic but ambitious standards, pushing for improved safety training and environmental reporting. These future efforts balance hard-won chemical knowledge with a desire to protect people and the planet — goals as practical as they are urgent in a world facing rising demand and shrinking patience for industrial mishaps.

Everyday Life Doesn’t Feature Phosphorus Tribromide—But Its Impact Sure Does

Phosphorus tribromide rarely ends up on family shopping lists or in garage cabinets. Still, many everyday essentials owe a lot to this chemical. In the world of organic chemistry, few compounds punch above their weight like phosphorus tribromide. I worked at a pharmaceutical lab during my post-grad years, and it was easy to spot recurring bottles labeled "PBr₃" tucked in the locked reagents cabinet. That’s not because folks wanted to give budding chemists extra headaches but because PBr₃ opens doors for reactions that simple acids or bases just can’t handle.

Transforming Alcohols, Building Blocks for Medicine

Start with alcohols and you can usually thank phosphorus tribromide for turning them into alkyl bromides. Those transformations don’t just interest chemists for fun—they help build specialty chemicals and key drug ingredients. One painkiller from a leading pharmaceutical company has an intermediate molecule that only comes together with a little help from PBr₃. Skipping this step leads to labs working twice as hard with half as much payoff. Nearly every organic chemist has a story of standing near a fume hood, hoping the telltale brown fumes signal another successful batch—care needed, but appreciation on tap.

Vital Role in Agrochemicals and Dyes

Phosphorus tribromide doesn’t show up in food or on farm fields, but its fingerprints do. Agrochemical research depends on fine-tuned molecules. The same reactions that produce those bright red dye molecules for clothing or stable pesticides for crops often begin with conversions enabled by PBr₃. Without it, more steps, waste, and higher costs tag along. I’ve seen batch records from factories where swapping out PBr₃ led to more wasted product—and frustrating mornings troubleshooting what seemed like simple chemistry.

Challenges for Health and Safety

Phosphorus tribromide isn’t without baggage. It reacts fiercely with water, putting out corrosive and toxic fumes. One splash or careless moment could prove serious. Industrial labs enforce strict handling measures—goggles, gloves, vented hoods, and meticulous documentation. I once watched a senior chemist halt an entire team’s work until a tiny bottle of PBr₃ was safely returned to its storage case, placing safety over speed.

Improving Chemical Safety and Efficiency

Not every lab or manufacturer enjoys the same resources or training. Accidents involving phosphorus tribromide have sparked stricter protocols and better equipment. Digital logs now replace old clipboard checklists, helping spot problems and track who handles the most reactive bottles. Substitutes for PBr₃ are in constant development, yet no clear winner matches its speed and power in certain syntheses. Better training, clear labeling, and investment in safety tech make a difference, but professionals still keep a wary respect for the substance.

Looking Ahead

Society rarely notices compounds like phosphorus tribromide, but their influence threads through medicine, agriculture, and even the color of clothes. Continuous innovation in chemical safety reduces risk, and new methods chip away at some of the more dangerous legacy reagents. Until safer routes handle the toughest transformations, phosphorus tribromide will keep playing its backstage part—enabling the science behind modern life while reminding chemists to keep their guard up.

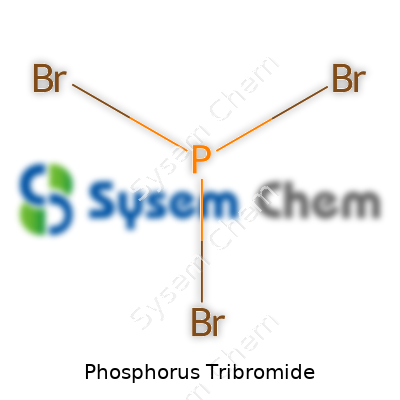

Breaking Down the Basics

Phosphorus Tribromide grabs attention for the simple reason that it plays a big role in the world of chemistry labs and industry. Its chemical formula comes down to PBr3. With one phosphorus atom combined with three bromine atoms, this compound turns up not just in chemical reactions but also in real-world manufacturing. It falls into the category of phosphorus halides, and the details of this molecule go beyond letters and numbers on a label.

Why the Formula Matters

The formula, PBr3, sits at the heart of how this substance behaves. If you’ve ever set foot in a chemistry lab or needed to make an organic compound, you’ve probably seen how useful phosphorus tribromide can be. It transforms alcohols into alkyl bromides pretty efficiently, helping researchers move from raw materials to useful products. Even outside the lab, the industry counts on phosphorus tribromide for pharmaceutical and agrochemical synthesis. You might not bump into it in daily life, but its presence hides in plenty of things built in industrial pipelines.

Real-World Importance and Experience

A chemical like PBr3 does not just stay locked in textbook examples. Back in college, I remember working with a bottle of phosphorus tribromide to help a team isolate a simple bromoalkane. The warnings on the label stood out to me just as much as the pungent odor when we teased the cap off. A spill would have spelled trouble: the reaction with water produces dense fumes and strong acids. In a controlled setup, though, nobody matches its ability to convert simple alcohols into compounds found in medicines and crop protectants.

Handling Safety and Health Risks

Direct exposure can be dangerous for both people and the environment. As a result, safety matters just as much as knowing the formula. Gloves and goggles come before anything else, and chemical fume hoods are not optional. Anyone managing phosphorus tribromide has to stay aware of how easily it reacts with moisture, forming hydrogen bromide gas and phosphorous acid. These byproducts cause inflammation, burns, and long-term damage if someone skips precautions.

Supporting Responsible Chemistry

The responsible use and management of compounds like phosphorus tribromide keep both chemists and the public safe. Facilities invest in robust training to help staff react quickly to unexpected leaks or spills. Regulations covering storage and transport are there for a reason; if the compound escapes containment, it creates risks from toxic exposure. The deep orange liquid may look simple, but its effects demand respect.

Potential Solutions to Risks

Reducing hazards from phosphorus tribromide often means controlled handling, strict operational procedures, and proper disposal. Storing the chemical away from moisture blocks dangerous side reactions. Some companies now shift toward alternative reagents for bromination when possible, turning to less reactive, more manageable chemicals. These efforts lower health dangers and help protect the local environment.

Knowledge Fuels Better Choices

Knowing the chemical formula of phosphorus tribromide—and what it stands for—empowers people to understand both its value and its risks. Proper training and a solid understanding of the compound shape a safer, more responsible chemistry industry.

Understanding the Risks

Phosphorus tribromide draws quick reactions from most chemists—both for what it can do, and for how unforgiving it acts in the lab. Known for its pungent odor and aggressive nature, this substance reacts fiercely with water, forming hydrobromic and phosphorous acids. I remember my first encounter with it: the lesson stuck because a single drop on a benchtop fizzed loudly, announcing its presence. It never pays to underestimate the danger of serious chemical burns, toxic fumes, and even fire hazards it brings along.

Key Storage Approaches

Always pick a cool, dry location—any hint of humidity brings trouble. Laboratories and storerooms should keep phosphorus tribromide away from sources of water, steam, or even moist air. Store it only in tightly sealed glass bottles or compatible metal containers with non-reactive linings. Never use containers with metal parts that might corrode. Acid cabinets—especially those that boast robust ventilation—offer a safer way to prevent fume buildup from accidental leaks.

Keeping incompatible chemicals apart is not just a best practice; it is a rule worth repeating out loud. Store phosphorus tribromide far from oxidizers, strong bases, and substances that contain alcohols or amines. A spill can lead to fire or toxic vapor releases, and there is no substitution for strict segregation.

Safer Handling—Experience Matters

Work under a chemical fume hood; just cracking open the bottle outside one fills the room with acrid vapors. Always use proper gloves—nitrile or neoprene withstand brief exposure better than thin latex. Gone are the days of eye protection taking a backseat; modern labs expect goggles and face shields as standard. Accidents can happen in a flash, and a single missed precaution can leave lasting damage.

Transferring this chemical requires glass pipettes or dedicated syringes. Avoid pouring, since splashing raises the risk of burns to hands and face. Never forget to double-check the integrity of containers before and after use. Training grows into habit, but nerves and attention still play the biggest role. If you smell that biting odor outside the expected boundaries, it’s already too late for caution.

Ventilation and Emergency Response

A good ventilation system—beyond a basic hood—keeps the workspace breathable and safe. I’ve seen labs with constant negative pressure rooms for just this reason; leaks get contained by the system before they can cause harm. Even with every precaution, accidents can slip through. Eyewash stations and safety showers must stand nearby and stay unblocked. Every second counts during a spill or splash, since injuries escalate quickly.

Managing Waste

Frequent disposal mistakes cause the most accidents. Never tip excess phosphorus tribromide down the drain or toss it in ordinary trash. Collect all residues in tightly sealed, chemically resistant containers, clearly labeled with hazard warnings. Certified chemical waste handlers handle the final removal. Skipping this step not only endangers the lab, but also the surrounding community and local water systems.

Training and Continuous Vigilance

Experience beats textbook rules every time. Regular drills and refreshers keep the right moves at the top of mind. Mistakes often happen when training lapses or routines get taken for granted. Juniors get paired with veterans for good reason; close mentorship matters more than any standard operating procedure. Every laboratory professional should know exactly where to run and what steps to take if something goes wrong with phosphorus tribromide.

Every bottle demands respect, not just for the science it makes possible, but for the consequences it brings for those who handle it. Safety means knowing every risk, and meeting each with strict action, without shortcuts.

Real Dangers in the Lab and Workplace

Phosphorus tribromide isn’t something anyone wants to take lightly. It reacts with water so fast that even a tiny spill can fill the air with white fumes of hydrogen bromide and phosphorous acid. Breathing that in burns your throat and lungs, leaving a stinging pain that sticks with you for hours. Last year, I caught just a whiff in the corner of an old fume hood—I thought I could dodge it, but my eyes wouldn’t stop watering and my nose burned for the rest of the day. The risk goes far beyond one uncomfortable experience. If a bottle cracks or breaks open, you look at chemical burns on the skin, eye injuries, and a potential fire risk if it comes into contact with flammable materials.

Over time, unsafe storage habits can lead to disasters. Phosphorus tribromide will eat through many plastics and metal containers if you store it wrong. One forgotten spill can corrode a cabinet or seep into a workspace, putting everyone in harm’s way. The environmental hazard lingers too—spilled chemicals like this seep into drains and attack aquatic life, causing damage that won’t be obvious until fish start dying downstream. OSHA lists the stuff as hazardous, with tight exposure limits. Even with protective gear, mistakes happen when people lose focus for a moment, and with phosphorus tribromide, small mistakes carry large consequences.

Keeping People Safe: What Works on the Ground

A good safety setup starts with airtight containers made from glass or compatible plastic. The storage space should be cool, dry, locked, and posted with warning signs you can’t miss. Ventilation isn’t just for show; every container gets opened and handled only in a fume hood, and even then, you keep your face and arms as far as possible from the action. I’ve learned to wear face shields, splash-resistant goggles, and chemical-resistant gloves every time, no matter how small the task. It sounds like overkill, but one splash on bare skin lets you know no level of protection is too much.

Alongside personal protection, spill kits and neutralizing agents sit close by. I keep sodium bicarbonate on the shelf because water alone won’t get rid of phosphorus tribromide safely—it needs neutralization. If a spill happens, workers evacuate until a trained responder cleans it up with the right tools. Emergency showers and eyewash stations wait around every corner, and you test them regularly. The key is treating every transfer or reaction with suspicion, never assuming equipment is leakproof. I check seals. I check gloves. I check everything before touching the bottle.

The Value of Training and Preparedness

Everyone handling phosphorus tribromide gains reassurance from serious training before the first experiment. Simple, clear instructions save lives—no one forgets that video of someone failing to react quickly after an accidental splash. Laboratories and factories invest in refresher courses every year, and teams rehearse spill scenarios just like fire drills. That way, in a real emergency, responses come fast, not panicked. Regular health monitoring for workers also helps. Some teams rotate shifts so no one receives long-term exposure even at permitted levels, and periodic air quality checks pick up leaks or slow releases before anyone feels the symptoms.

No one plans for things to go wrong, but with dangerous chemicals, the wise approach relies on expecting the unexpected and reacting fast. I remember every successful shift working with phosphorus tribromide not because nothing happened, but because everyone committed to safety every single time. That commitment keeps people healthy and lets crucial work continue without disaster.

Getting a Handle on a Reactive Compound

Phosphorus tribromide isn’t a substance you’d want to toss in your backpack. This chemical, known for its role in organic synthesis and making brominated compounds, brings serious risks. Once exposed to air or water, it releases nasty fumes and corrosive hydrobromic acid. In the hands of experienced chemists, it’s a powerful building block. Outside the lab, it can cause fires, injuries, or property damage without warning. So people in charge of packaging and shipping this stuff have every reason to stay careful.

Materials and Containers Matter

Working with phosphorus tribromide starts with the right container. Steel drums with tight-sealing lids and glass bottles with extra-robust coverings both find their place, but nobody trusts ordinary plastics or loosely-sealed vessels. This material chews through many plastics and corrodes metal if the lining fails. Steel drums lined with specialized coatings, like phenolic resins, offer a tough barrier. When smaller amounts head toward research labs, thick amber glass bottles take the lead, each capped with a PTFE (polytetrafluoroethylene) seal. Seals need attention because even a hairline crack can let vapor escape—and that’s bad news for anyone nearby.

Separation from Water and Air

Exposure to moisture turns phosphorus tribromide into a hazard. Freight teams keep it away from humid environments and pack absorbent materials within containers. Desiccant packets show up more often than you’d think. Even inside drums or glass flasks, people double-bag and wrap materials with layers of inert, water-resistant plastic. Before containers even leave the manufacturing site, company staff often test seals and examine for corrosion or tiny leaks. Missing a problem here courts disaster. One leaky package can turn a warehouse into a hazmat zone.

Regulations and Real-World Shipping Challenges

Phosphorus tribromide falls under strict hazardous materials rules. The United Nations pins it with a UN number, and local agencies tag it for hazardous transport. Trained shippers need special labels, hazard diamonds, and detailed manifests. Forklift drivers follow routes designed to avoid bumps, heat sources, or high-traffic walkways. In my experience, every time an unexpected process shortcut gets suggested—maybe swinging by a noncertified carrier or using older containers—someone on the team always steps up to block that kind of thinking. People remember the stories: damaged steel drums, acid smoke, evacuations. In some years, insurance companies demanded photos of sealed drums at every step, building a habit of diligence rooted in painful incidents. Every so often, a government inspector makes a surprise visit. Inventory checks get intense, and documentation runs deep, but no one skips details. Compliance isn’t just law—it's a commitment to protecting lives and property.

Looking for Smarter Solutions

Accidents around reactive chemicals force the entire field to innovate. Some suppliers now offer smaller container sizes for high-reactivity substances, reducing the quantity in transit and lowering the impact of mishaps. Bulk buyers break large shipments into smaller, independently-sealed units. Redundant containment systems—double-walled drums, secondary packaging for glass—reduce the chance of failures. Shipping routes get rerouted around densely populated areas, and truck drivers take extra hazardous material training, including emergency spill drills. New tech even tracks containers with GPS and temperature sensors, beaming real-time alerts to logistics teams if conditions change. This helps people fix problems before they grow out of control.

Bringing Safety Home

I’ve seen the sharp difference between a well-managed shipment and a careless one. Modern supply chains still face plenty of surprises, but relying on a culture of caution, strict compliance, and thinking ahead keeps dangerous materials like phosphorus tribromide on the safe side. People in the business share lessons, not just for insurance or legal reasons, but because someone’s day—or life—might depend on it. Safe packaging and shipping come down to respecting the chemistry, double-checking the process, and stubbornly refusing to cut corners.